新闻中心 +MORE

-

【QIAD】总结表彰 | 公司召开2023年度总结...

玉兔克坚不寻常,总结迎春聚表彰。觥筹交欢庆实绩,金龙生辉呈岁祥。2月6日下午,公司在大连海鲜钻石店召开...

-

【QIAD】学习培训 | 公司召开全过程工程咨...

为进一步指导和规范公司全过程工程咨询服务活动,2024年1月12日,公司组织召开全过程工程咨询实施指南宣贯...

-

【QIAD】争优创先 | 青海省院勘察的省委党...

近日,中国建筑业协会、中国施工企业管理协会评选的2022-2023年度国家级优质工程获奖名单揭晓,由我院岩土...

-

【QIAD】抗震救灾 | 青海省院受命再出征...

2023年12月18日23时59分,甘肃省临夏回族自治州积石山县发生了6.2级地震,我省海东市民和回族土族自治县、...

-

【QIAD】喜报 | 公司获评青海省企业信用协...

2023年12月25日,青海省企业信用协会和青海省江苏商会联合召开“携手奋进启新程、同心筑梦赢未来——2023年...

-

【QIAD】抗震救灾 | 青海省院奔赴灾区开展...

12月18日23时59分,甘肃临夏州积石山县发生6.2级地震,造成与之相邻的青海省海东市民和、循化、化隆等县区...

-

【QIAD】学习宣传 | 公司组织召开中国工会...

11月23日上午,公司召开“中国工会十八大、青海省第十五次工代会精神宣贯会”,公司党委委员、工会主席邹继...

-

【QIAD】互学互通促合作,交流探讨谋发展 |...

9月27日,乐竞体育(中国)股份有限公司(以下简称青海省院)、青海省土木建筑学会在青海省院六楼...

-

【QIAD】喜报 | 祝贺公司10名员工顺利通过...

近期,从中国人事考试网公布的2022年度全国各类专业技术人员注册资格考试中获悉,公司又有10名员工顺利通过...

-

【QIAD】公司组织开展主题教育专题党课活动...

根据《学习贯彻习近平新时代中国特色社会主义思想主题教育的实施方案》的要求,8月25日上午,公司在六楼会...

乐竞体育(中国)股份有限公司 +MORE

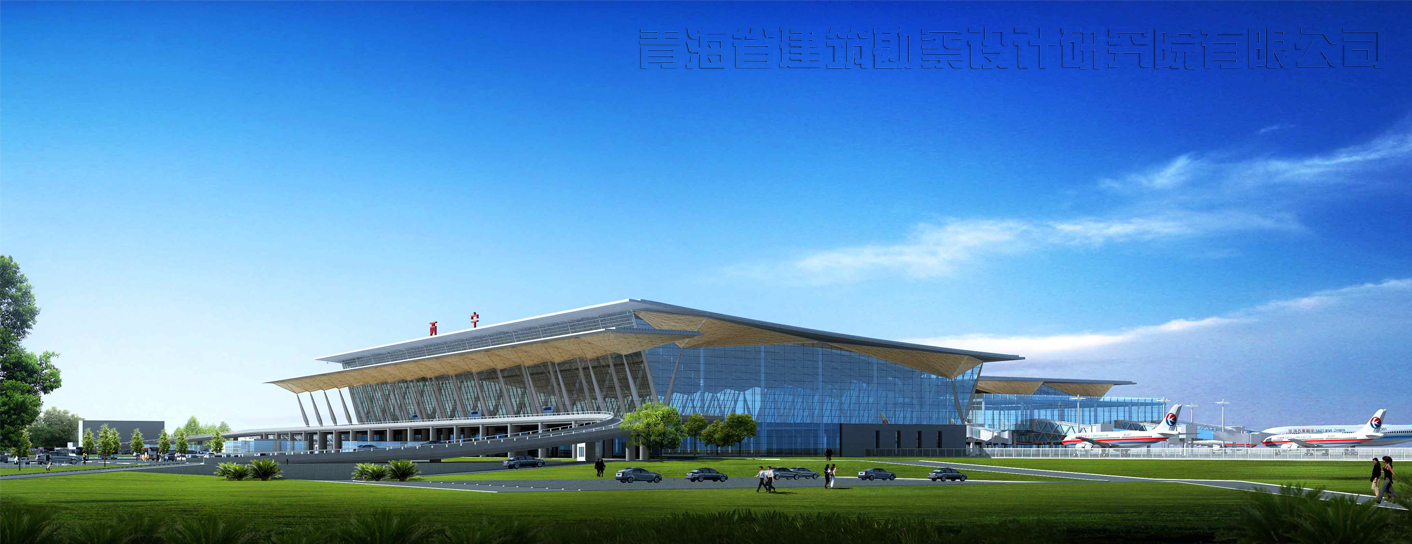

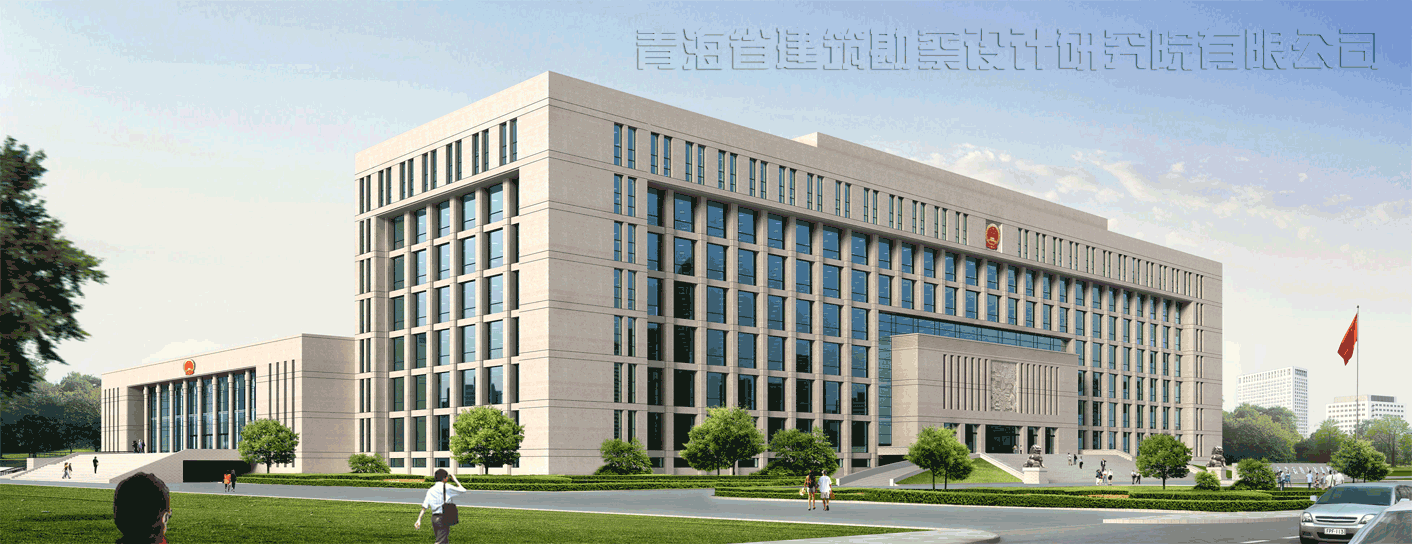

青海省建筑勘察设计研究院有限公司始建于1956年,2006年由青海省建筑勘察设计研究院转 制为有限公司,是青海省一家具有国家甲级勘察、设计资质的单位,也是青海省内设计单位龙头企业。公司注册资本2000万元,公司同时具有甲级建筑工程承包资 质、甲级工程咨询资质、甲级工程监理资质、乙级市政设计资质、工程造价咨询乙级资质和丙级测绘资质等。 公司现下设四个设计所、岩土公司、工程造价咨询部、测绘工程部、总承包公司、技术... [查看详情]

公告 +MORE

- 【QIAD】公告 | 西宁... 09/23

- 【QIAD】公告 | 西宁... 09/23

- 【QIAD】公告 | 西宁... 09/24

- 【QIAD】中标结果公告... 07/13

- 【QIAD】公示 | 西宁... 10/11

- 【QIAD】公示 | 西宁... 10/11

- 【QIAD】招标代理公示... 10/14

- 【QIAD】公告 | 西宁... 03/07

- 【QIAD】中标公示 | ... 03/21

- 盈建科结构设计软件V4... 03/28